zero + one

zero + one is a collaborative apparel research project that brings together the design benefits of alternative pattern cutting methods of zero waste and one-piece patterns.

Collaborative designers: Deb Cumming and Holly McQuillan

photographer: Bonnie Beattie

model: Claartje ten Berge

zero + one is a collaborative apparel research project that brings together the design benefits of alternative pattern cutting methods of zero waste and one-piece patterns. Zero waste pattern cutting is driven by sustainable motivations to create no or very minimal textile waste, often with the use of multiple jigsaw piece planning. One piece patterns can derive minimalism in aesthetics and production with reduced cutting and construction. Often looser, oversized garment designs are considered as more comfortable for the wearer. However, movement of the body is predominantly within the voluminous interior space rather than in relation to the exterior shell as required for more functional fashion wear. With increased consideration given to a sense of well-being and comfort in a broader range of clothing, designers are looking to satisfy emotive and physical needs of consumers.

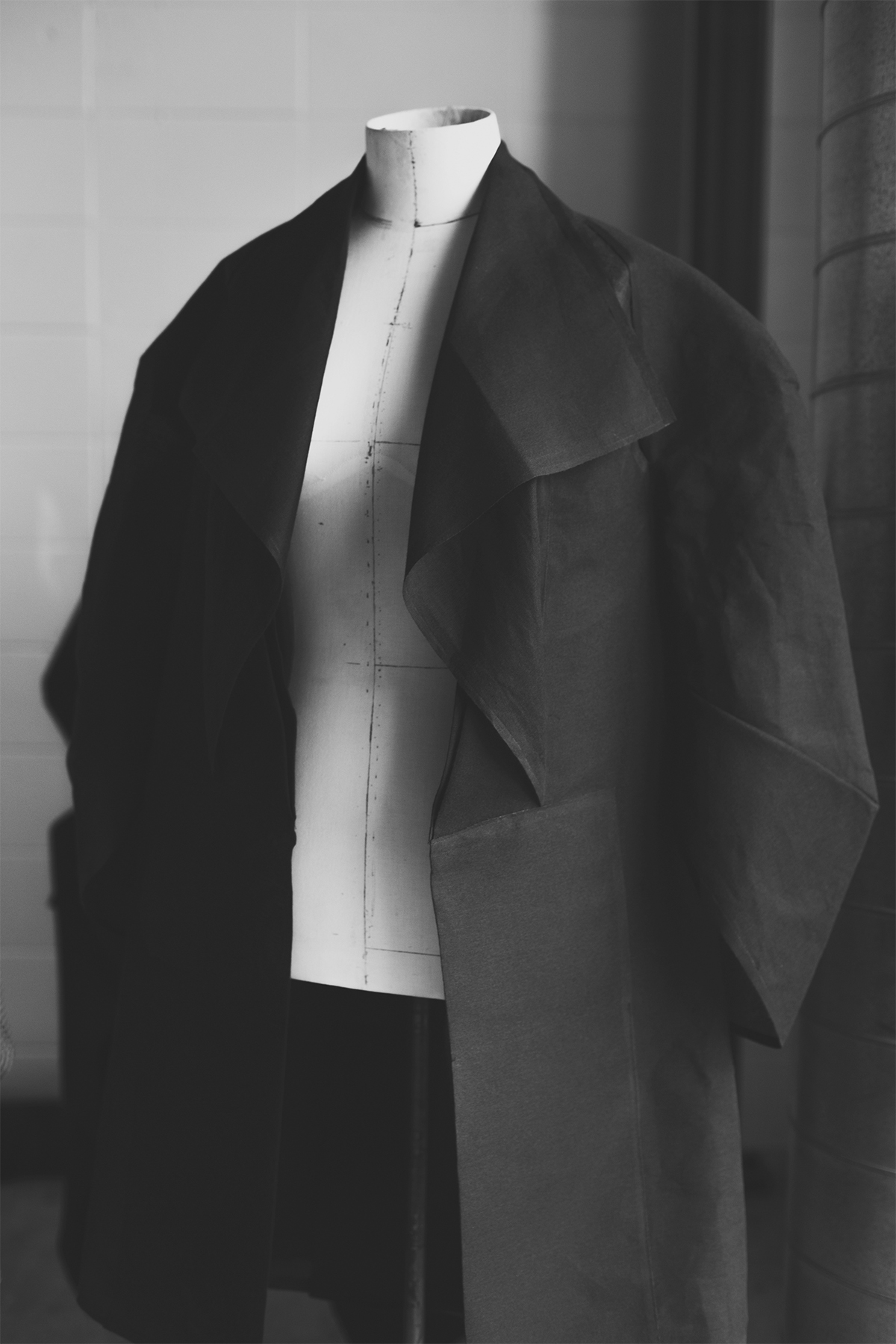

Gauze Coat

Deb Cumming and Holly McQuillan

methods: drape on body, zero waste fabric use plus one-piece pattern planning, prototyping, CAD pattern.

design elements: geometric folded volume, fabrics- cotton gauze 200cm x 150cm, zero waste one-piece pattern, folded collar and front opening, built-in oversized pagoda sleeve including short inner sleeve shell for strength, outer-sleeve front shoulder gusset opening, triangular dart at elbow shaping, under arm vertical lift, built-in pattern pocketing, lower back inverted pleat, strengthened double upper back and neck shapes.

zero waste construction and recycling: reduced seaming for manufacture, tape fused internal curved and straight cut lines for reinforcing and finishing, cut tape lines and overlapped seaming, selvedge usage. garment designed for disassembly and pattern reconstruction by refusing cut lines for textile recycling.

Drape Coat

Holly McQuillan

methods: drape on live fit model, CLO 3D pattern visualization, zero waste fabric use plan, prototyping, CAD pattern

design elements: collapsed volume, felted wool fabric 190cm x 160cm, zero waste pattern, drape front opening, back neck cutaway, built-in pattern oversize sleeves, elbow seam curvature, under arm vertical lift, sleeve hem opening, built-in pattern pocketing.

zero waste construction: reduced seaming for manufacture, overlap seaming, deconstructed edging, selvedge inclusion.

Reverse Coat

Deb Cumming

methods: drape on live fit model, one-piece pattern, minimal waste fabric use, prototyping, wear testing, CAD pattern

design elements: pod or swing back functional volume, reversible garment capacity, one piece pattern outer and inner fabrics- wool/ waterproof fabric 2x 160cm x 150cm, zipper front opening, built-in contoured full hood, built-in oversized upper-arm sleeve- elbow seam curvature and pleat, under arm vertical and forward lift, muscle back arm seam for multiple fit shoulder/arm size, built-in pattern pocketing, hood and back volume adjusted by draw-cords, embroidered eyelets.

construction: reduced seaming for manufacture, fully lined.

zero + one explores experimental pattern cutting to optimise volumetric fashion shapes with increased comfort and movement for the wearer, and a sustainable practise of reduced textile waste. The fashion and textiles industry is the second largest generator of waste in the world. From textile manufacture through to end-of-life, clothing has a massive impact on both natural and human resources. In conventional garment production, an average of 15% of the fabric is unused. It is estimated that this will add up to around 60 billion square meters of discarded cloth worldwide, from the making of around 80 billion garments. This pattern design work attempts to address waste generation primarily at the first stages of apparel production and facilitates post-consumer regeneration design.

Drape Coat 190cm x 160cm

Reverse Coat 2 X 165cm x 150cm

Gauze Coat 200cm x 150cm

The method used in creating the zero + one prototypes commonly utilizes draping a fabric dimension directly on the live body. The fabric is wrapped, cut, overlapped and folded, ensuring free arm movement and shoulder balance as integral to the loose shape dimension. Draping on the live body and the use of CLO 3D computer visualisation software, allows a study of the properties of the varied fabrics and how they perform.

The process involved complex and fine manipulations of line and shape, making visual corrections alongside pattern planning to utilise the fabric fully for the functional purpose of balance, movement and form. CLO eliminates the need for excessive fabric waste in toiling prior the prototype stage. Even though the coat designs are varied in volumetric form and functional design detailing, the CAD patterns show abstract configurations and geometries that are zero or minimal in fabric waste.

Building on current leading research in zero waste design and production strategies, this research also addresses the post-production stage of the garment life cycle. Post-production waste is generated when garments themselves are discarded. The simple 2-dimensionality of fabric use, provides the potential for reassembly back into original shape for second generation designs. This combined alternative pattern method using zero waste and one piece pattern cutting, and their adaptive construction methods, can influence new ways of apparel design and production to benefit the wearer and apparel industry efficiency.